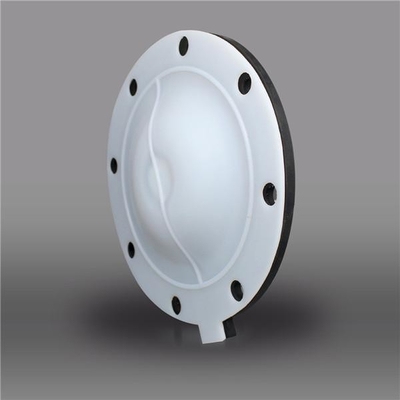

Sanitary Pump Composite Diaphragm

Introduction:

The patented rubber back cushion structure attached to a reinforced rubber back cushion with a high-performance material has a wide range of flexible life and can operate in most chemical environments. Chemical inertness and temperature stability, long service life means more time to change the frequency of low, so reduce maintenance costs, complete specifications, suitable for most brands of pumps and with the most specifications size.

Diaphragm valve rubber PTFE composite diaphragm is made of advanced EPDM EPDM or NBR nitrile rubber as the main body, in its effective sealing part composite by special activation processing of 100% pure PTFE shell, mainly suitable for food, chemical, pharmaceutical and other industries.

Diaphragm valve rubber PTFE composite diaphragm main advantages:

1. 100% pure PTFE sealing surface, a clean and pollution-free sealing surface.

2. Special composite process, PTFE firmly glued to the rubber elastomer, prevent delamination and leakage.

3. In the electronics industry, chemical plants and pharmaceutical factories are options.

4. Resistant to chemical media other than acid and alkali metals and element fluorine.

5. Good rigidity, strength and compression, rebound, compensation performance, can meet high pressure and harsh conditions.

About us:

In diaphragm industry more than 30 years, my company has advanced processing technology and professional technical team, existing tens of thousands of moulds, has rapid matching scheme, solved because of less mould, unable to form a complete set of need new mould trouble, also greatly increased the efficiency of supply, lets customers try so hard to use products delivery to the customer's hands as soon as possible. Our company also supports customized products without molds. Large quantities of products can be exempted from mold fees. The design of new molds is developed by the main designer of the company, which ensures that the products after production can achieve customer satisfaction!

Our service:

1. Packaging is neutral packing or customized packing.

2. We will reply you within 24 hours.

3. We will also provide you with good after-sales service.

4. OEM or ODM orders are welcomed.

5. Trial orders are acceptable.

6. High quality and factory price.

7. 100% ensured the quality.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!