Code 14 EPDM Rubber Diaphragm Chemical Industry Environmental Engineering

Application examples

• Water treatment plants, washing and cleaning installations

• Plants for the food and foodstuff industries, the chemical industry and electroplating

• Equipment for the photographic industry, laboratory, analytical and medical apparatus

Description

The GEMÜ code 14 EPDM diaphragm has been developed for use in industrial applications, for example in the chemical industry, environmental engineering and the processing industry.

Technical specifications

| Media temperature |

-10 to 90 °C |

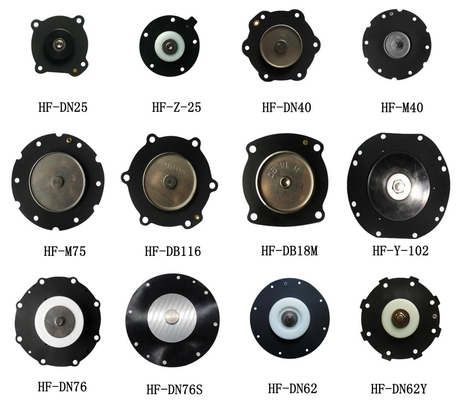

| Diaphragm sizes |

10 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 |

| Diaphragm materials |

EPDM |

Features:

| Low gas permeability |

| Suitable for vacuum |

| Ozone and weather resistant |

| Can be used with steam for short periods of time |

For abrasive and contaminated media: Full bore diaphragm valves and lined diaphragm valves

The minimal deadleg internal contour and the support of the diaphragm by a compressor provides optimum flow conditions and the best seal properties on GEMÜ full bore diaphragm valves. Lined diaphragm valves from GEMÜ combined with a suitable seal material offer even better resistance to numerous lyes, acids and other corrosive, abrasive and contaminated media.

Available materials: NBR, CR, natural rubber and EPDM

For sterile and hygienic applications: seal system

GEMÜ developed its seal system for diaphragm valves with a sealing weir up to DN100 over three decades ago. A circular sealing bead in the valve body creates a defined external sealing point. This minimizes the ring-shaped gap between the diaphragm and the valve body and makes this seal system particularly suitable for applications in the pharmaceutical, biotechnology and cosmetics industries.

The membranes (especially the Elastomers) are subject to natural aging.

To ensure the quality and durability of the membranes during storage influence as little as possible.

The service life can vary depending on the application. Diaphragms are wearing parts and must be checked at regular intervals and replaced if necessary. The maintenance intervals to be provided are very much dependent on the application and cannot be precisely defined in advance. The individual maintenance cycles are usually determined on the basis of empirical values or the maintenance history. If the membranes are subject to particularly high loads, e.g. due to frequent sterilization or high switching cycles, it may be necessary to shorten the maintenance cycles.

Diaphragms, which are used predominantly in sterile applications

***** Highest mechanical load capacity

Note:

Since plastics and elastomers are subject to natural aging, we recommend observing the GEMÜ storage conditions for shut-off diaphragms. You thereby guarantee maximum storage and service life of the diaphragms.

The temperature values are indicated irrespective of operating pressure and diaphragm size and apply to water and/or inert gases. The permissible operating pressure decreases with rising temperature and nominal size. Only specially designated diaphragms should be used for steam. The permissible operating pressure results from the steam pressure diagram.

1. Packaging is neutral packing or customized packing.

2. We will reply you within 24 hours.

3. We will also provide you with good after-sales service.

4. OEM or ODM orders are welcomed.

5. Trial orders are acceptable.

6. High quality and factory price.

7. 100% ensured the quality.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!