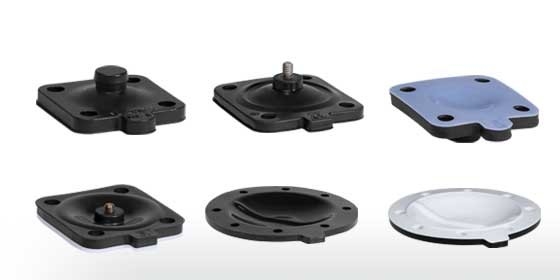

Fabric Reinforced Code 19 EPDM Diaphragm Reduced Adhesive Behaviour

Application examples:

• Water treatment plants, washing and cleaning installations

• Plants for the food and foodstuff industries, the chemical industry and electroplating

• Equipment for the photographic industry, laboratory, analytical and medical apparatus

Description

The GEMÜ code 19 diaphragm is a one-piece peroxide-cured EPDM diaphragm that has been developed for use in pharmaceutical and biotechnological applications as well as for the food and beverage industries. The diaphragm displays improved setting behaviour and reduced signs of wear, which enables high switching cycles and therefore an increased service life. The GEMÜ code 19 EPDM diaphragm is suitable for use with abrasive media.

Technical specifications

- Media temperature: -10 to 100 °C

- Sterilization temperature*: max. 150 °C

- Diaphragm material : EPDM

- Diaphragm sizes : 8 | 10 | 25 | 40 | 50 | 80 | 100

Features

- Fabric reinforced (diaphragm size 10 to diaphragm size 100)

- Low signs of wear and optimized setting behaviour

- High performance capability thanks to improved positioning of the fabric insert

- Greatly reduced adhesive behaviour (no adhesion on the valve seat) of the diaphragm as a result of new material compounding

- High sealing values and low deformation through steam use

- Extremely long service life thanks to good material properties

- Simple mounting thanks to the rubber pin that is vulcanized in place (diaphragm size 8)

- Simple and defined mounting thanks to the threaded pin that is vulcanized in place with integrated screw-in stop (diaphragm size 10 to diaphragm size 100)

Important notes:

Due to the setting behaviour of elastomers, the compression of the diaphragm must be checked before commissioning the system and periodically during use and its bolting tightened if necessary (for valves in sterile applications once additionally after the first sterilization cycle). Other regular inspections during operation are recommended depending on the use of the valves.

Attachments and accessories such as seal adjusters, stroke limiters, optical position indicators, electrical position indicators, positioners and process controllers must be recalibrated after changing the diaphragm and / or readjusting the diaphragm (see relevant function description). The setting of manual valves with a seal adjuster must also be readjusted.

The membranes (especially the Elastomers) are subject to natural aging.

To ensure the quality and durability of the membranes during storage influence as little as possible.

The service life can vary depending on the application. Diaphragms are wearing parts and must be checked at regular intervals and replaced if necessary. The maintenance intervals to be provided are very much dependent on the application and cannot be precisely defined in advance. The individual maintenance cycles are usually determined on the basis of empirical values or the maintenance history. If the membranes are subject to particularly high loads, e.g. due to frequent sterilization or high switching cycles, it may be necessary to shorten the maintenance cycles.

Measures for storage of membranes

• Observe the relevant standards (e.g. ISO 2230 – regulations for the storage of elastomers)

• Observe the storage temperature -10 °C to +25 °C (preferably 15 °C).

• Protect from light, especially with a high UV component (sunlight and artificial light).

• Maintain relative humidity below 65%

• Only store membranes in rooms that do not contain any ozone-generating equipment (e.g. electric motors), solvents, fuels or chemicals, etc. Membranes should be protected from strong air changes and draughts. If necessary, store in airtight containers or bags

• Only use foils without plasticisers for packaging

• membranes relaxed, i. H. store without tension, pressure or other deformations

• Do not hang the membranes in the holes

Diaphragm dimensions:

* Diaphragm size

The thread of the diaphragm pin "W" corresponds to Whitworth standard.

1. Packaging is neutral packing or customized packing.

2. We will reply you within 24 hours.

3. We will also provide you with good after-sales service.

4. OEM or ODM orders are welcomed.

5. Trial orders are acceptable.

6. High quality and factory price.

7. 100% ensured the quality.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!