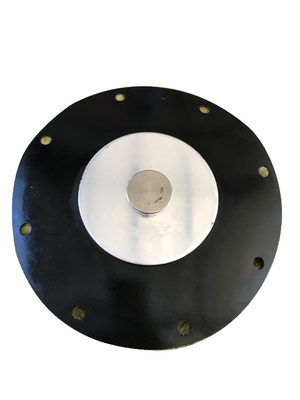

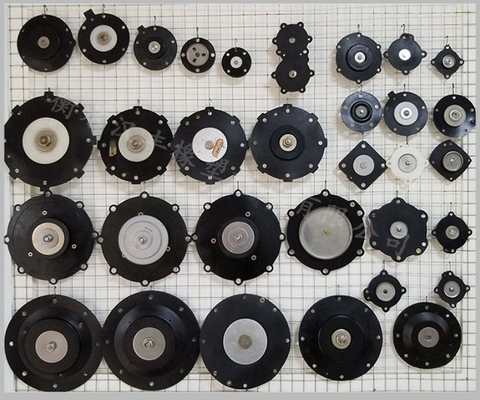

Pulse Solenoid Valve Rubber Diaphragm for Precipitator Equipment Aging Resistance

The pulse valve diaphragm is a whole piece of high-quality rubber diaphragm installed with a riveting head used to block the compressed air pipeline or the air outlet of the blocking valve, a venting unloading hole and a bolt hole for fixed support around it. It is the key control part in the electromagnetic pulse valve.

| Product Materials |

NBR,NR |

| Operating Temperature |

-20℃~80℃ |

| Service Life |

≥1000000 times |

| Usage Scenario |

Bag filter devices /precipitator equipment |

Features:

Fabrication technics of textile makes the product tear resistance stronger

High quality raw materials ensure the excellent performance of the material itself

Working principle:

The electromagnetic pulse valve diaphragm divides the pulse valve into two air chambers. When the pressure of the rear air chamber makes the diaphragm close to the air outlet of the valve, the pulse valve is in a closed state, the pulse controller outputs a signal to move the armature of the pulse valve, the vent hole of the air chamber behind the valve is opened, and the rear air chamber quickly loses pressure, making the The diaphragm moves backward, the compressed air is blown through the outlet of the valve, the pulse valve is in the open state, the injection starts, the electrical signal output by the pulse controller disappears, the electromagnetic pilot of the pulse valve is reset, the vent hole of the rear air chamber is closed, and the back When the pressure of the air chamber rises, the diaphragm of the pulse valve is close to the air outlet of the valve, the pulse valve is in the closed state, and the injection stops. The length of the injection time is controlled by the controller.

Application:

Referred to the dust collector, it applies to waste gas dust filtering of Cement plant, Steel mill, Power station, Electrolytic aluminium factory, Incineration plant, crushing mixing conveying of Chemical plant, crushing mixing sieving grinding of Pharmaceutical plant, raw material mixing packing of Paper mill, bagging mixing of Dyeing mill, crushing gagging conveying and mixing of Fertilizer plant, crushing plasticzation conveying of Kilns, sawing polishing filing of Log mill, etc.

Our service:

1. Packaging is neutral packing or customized packing.

2. We will reply you within 24 hours.

3. We will also provide you with good after-sales service.

4. OEM or ODM orders are welcomed.

5. Trial orders are acceptable.

6. High quality and factory price.

7. 100% ensured the quality.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!